Problems when installing Epytec Tuning Brake Caliper Adapter ?

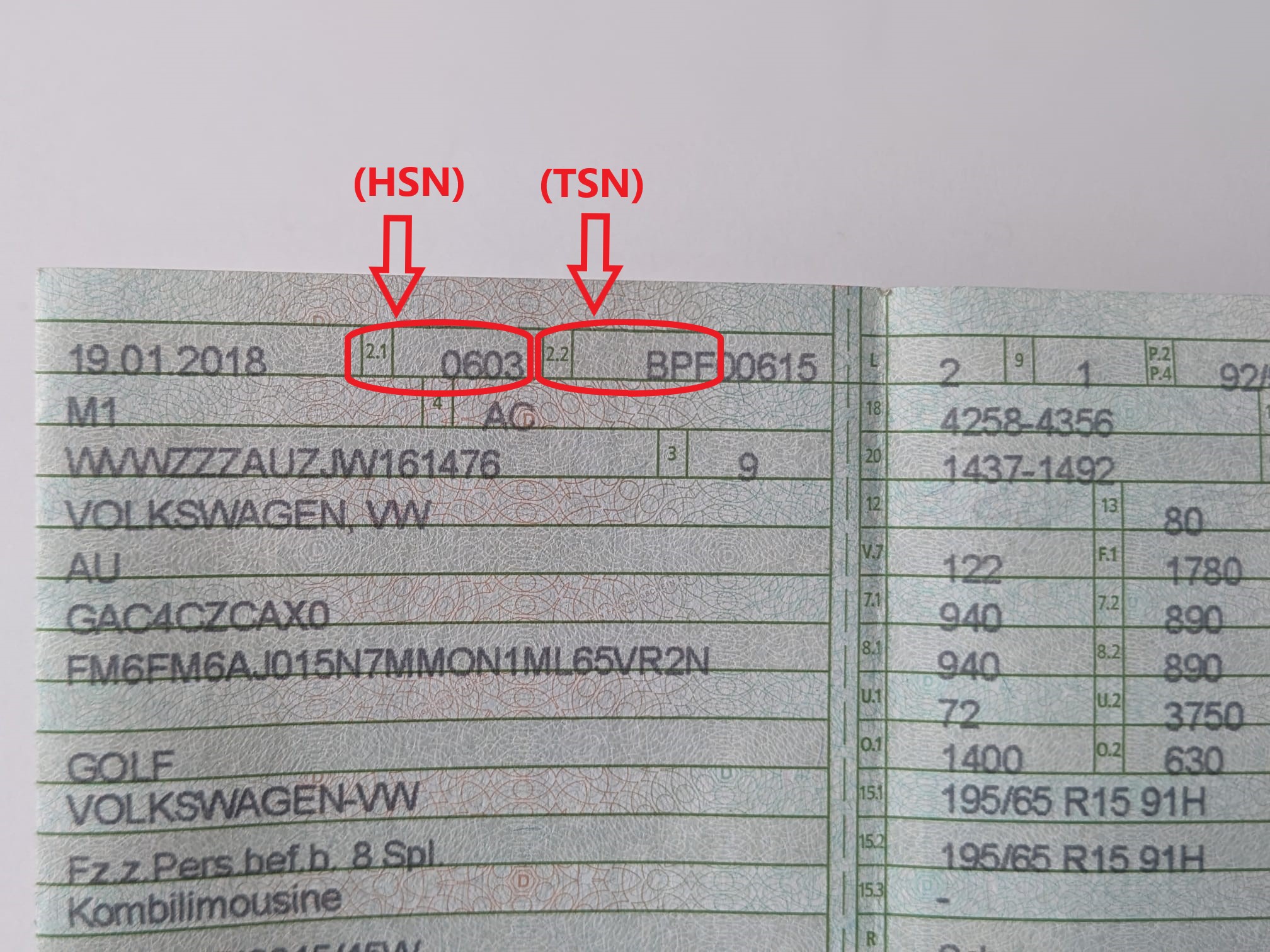

Problems when installing Epytec Tuning Brake Caliper Adapter ? Please make sure that you check the components that we have listed on the article page against your own. If they do not match 100%, the adapter may not fit because you are using different components. In this case, you simply have to get the right components. In the following, problems with the installation of Epytec adapters and their solutions are described.

The brake disc does not run centrally in the brake caliper

If the brake disc does not run centrally in the brake caliper, this can have several reasons. Here you will find all the reasons and solutions, please check the following points:

Wrong components

The most common cause is that the wrong components, such as brake discs or brake calipers, are usually used with Epytec Tuning Adapters.

Brake disc:

It is possible that the diameter of the brake disc is the same, but the cup depth is different. Please make sure to compare the part number, which we state in each item description, with the part number on the brake disc. If these do not match 100%, it is unfortunately the wrong brake disc and does not fit together with the Epytec Tuning Adapter. In this case, you can easily get the correct brake disc based on the part number.

Brake caliper:

It is often overlooked that the part number does not match 100% with the part number in our product description. For example, part number 996.351.426 is often confused with 996.352.426. Here, only one number is different, but the saddles have completely different dimensions and are therefore completely different.

Does the problem occur on both axles of my car?

Please check both sides of your vehicle, i.e. left and right axle. In the past, we have been able to determine massive differences, for example by rebuilding the steering knuckles or similar. Therefore, please check both sides of your vehicle. If there are differences on your axle, there are two possible solutions.

Solution 1:

In order to compensate for the tolerances on the axles, we have extra flat bushings in our programme so that the play can be compensated. You can easily order these directly here (click here).

Solution 2:

See if you can get an original axle carrier that has fewer tolerances.

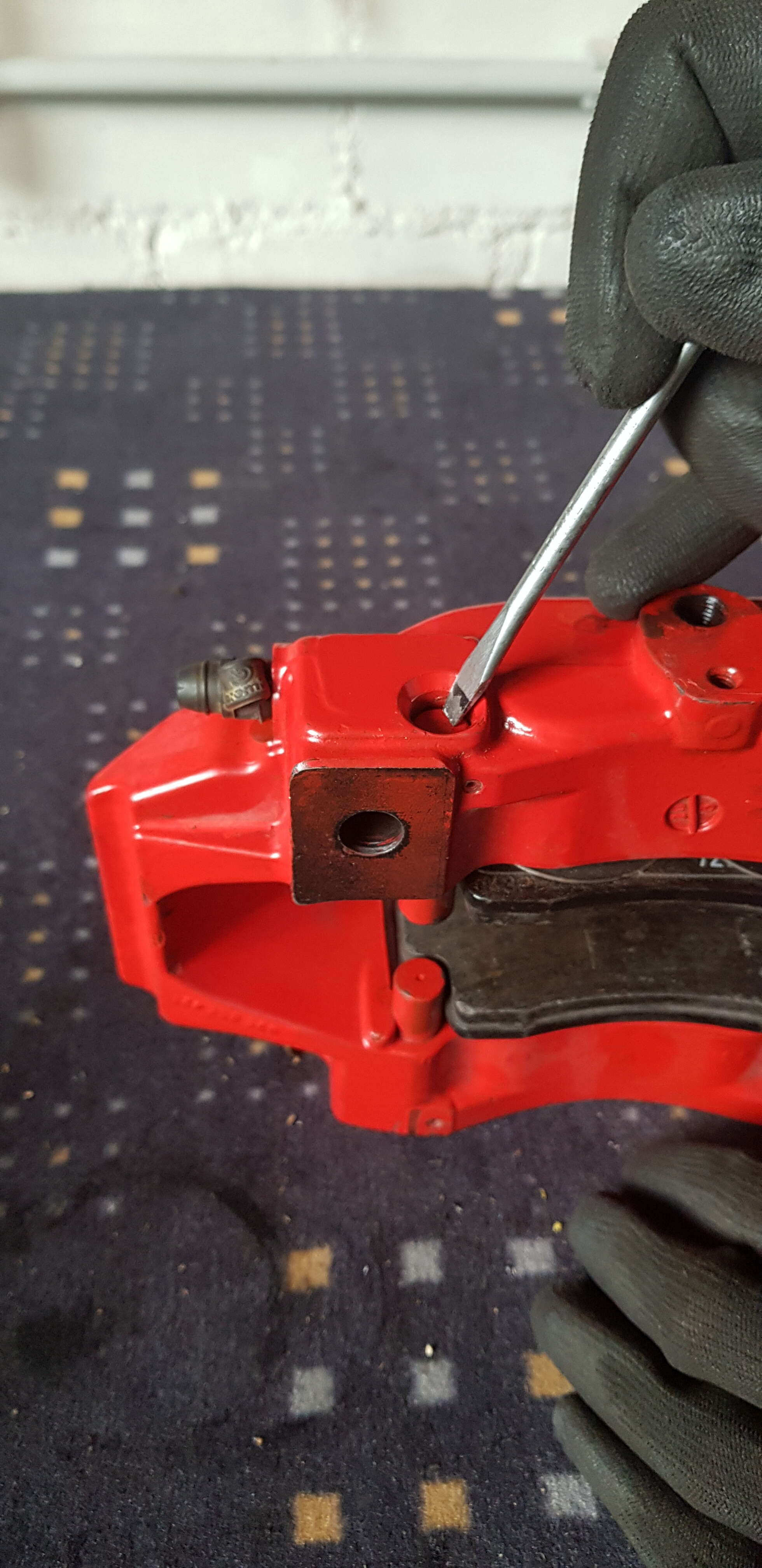

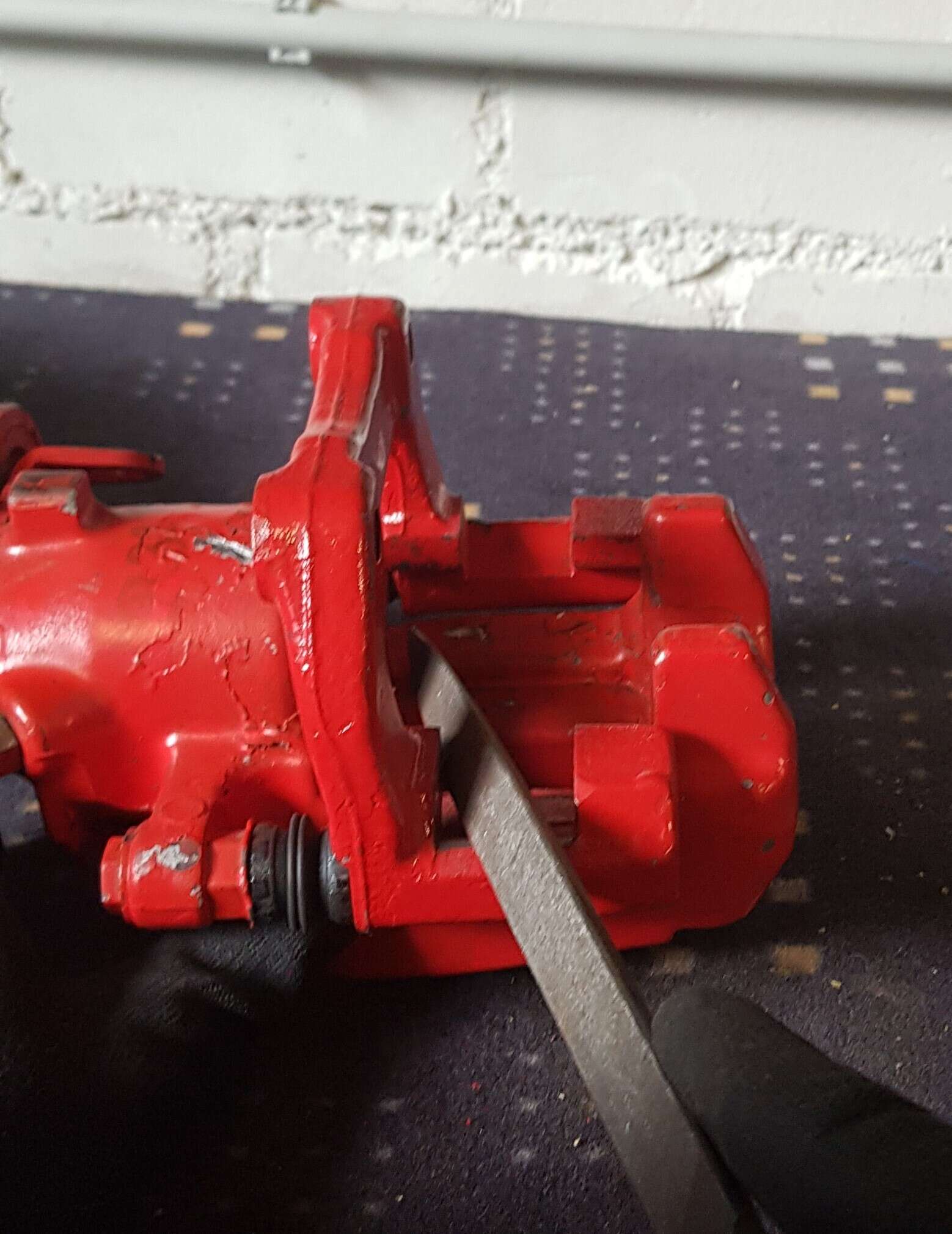

Is the brake disc rubbing against the pin that holds the brake pad?

If you have calipers that are equipped with a brake pad retaining bolt, you can make the perfect adjustment through them. You can easily adjust them by pressing them in or out. The reason for this is that Brembo and other manufacturers, using this technique, can often run the same calipers with different disc thicknesses. So it can happen that the same caliper with the same part number has different distances between the bolts. Since you can readjust the bolts and adjust them so that it no longer rubs.

Often there is a lot of paint on the bolts, so they are sometimes very difficult to adjust. It is advisable to remove the paint from the bolt beforehand and then press it in or out with a press. The following pictures show you how to proceed.

Rust on the wheel hub under the brake disc or the screw-on point of the brake caliper adapter ?

Please check that there is no rust or dirt under the brake disc or the brake caliper mounting point. If this is the case, please remove them with a wire brush so that the brake disc and the adapter can rest cleanly

Drive shafts and wheel hubs not pressed in correctly or pressed in too tightly

Tightening the drive shaft or the bolt on the wheel hub can cause the wheel hub to move significantly. This is also the case if it is tightened too much. Then it can happen that the brake disc does not run centrally.

Solution:

Please check whether you have screwed on the wheel hub as prescribed by the manufacturer. Make sure that you only test the adapter if all the components are screwed on correctly. If this is not the case, adjust it!

Likewise, there are always problems with the tolerances on the axles of the vehicle manufacturers. We have already been able to measure differences of up to 2mm on original axles. If you have checked all the above points and the disc still does not run centrally, you can compensate for the tolerances with our bushings. This way you can also get it exactly centred for your conversion.

You can easily order them directly here (click here).

Brake caliper cannot be fitted far enough onto the disc or rubs against the outer diameter of the brake disc.

If the brake caliper cannot be fitted properly from the outside or rubs against the outer diameter of the brake disc, this may be due to one of the following reasons.

1. wrong brake caliper carrier or wrong brake caliper

One of the most common causes is that the brake caliper carrier is the wrong one. Car manufacturers have produced carriers in different lengths, which means that one and the same brake caliper was produced once with long and once with short carriers in order to drive different disc sizes. If you have the wrong carriers for your conversion, then please get the correct ones and the conversion will fit.

2. the brake caliper grinds only 1-2mm on the outer diameter.

Here we have again the problem of tolerances, this occurs especially with brake calipers which are rebuilt, from other brands or do not have OE part numbers and often with cast brake calipers.

Solution:

Grind the upper edge of the caliper with a Dremel or file until the disc runs freely again.

Brake pad overhangs the brake disc

The brake pad is not an original spare part

Brake pads vary depending on the manufacturer. As a result, it can happen that the brake pads have more thickness at the top and therefore protrude significantly beyond the brake disc. Then you can grind a chamfer on the upper edge.

Wrong brake caliper

If the pad is too far over, you may also have the wrong caliper. st.

Solution:

Please be sure to check the part number to see if it matches our part number, which we have included in the product text. If the part numbers of the brake calipers do not match 100%, you have to get the matching / correct brake caliper.

Technically not possible

For a few of our caliper conversions it is technically not possible, because during the development of the Tuning Adapter the customer wanted to use a small rim size in combination with a large caliper.

In this case, a chamfer must be applied to the protruding part. >>Click here and see an example article where it does not work differently from the caliper to disc combination <<

The hole spacing of the brake calipers is not correct and cannot be mounted.

If this problem occurs, you have definitely bought the wrong brake caliper, often private sellers of these calipers simply give wrong data.

Solution:

Go back to the article description in our shop and look at the part number of the brake caliper, get this and the adapter will fit.