Conversion BMW E46 330i Touring with our flywheel item 639

Our customer Leo installed our flywheel item 639 for the M52/M54 engine in his BMW E46 330i Touring.

He wrote us a great installation guide for it - many thanks for that :)

Installation Guide: Lightweight Flywheel (Item 639) for BMW E46 330i Touring – Perfect solution for sportier throttle response with the M52/M54 engine

1. Introduction & Benefits

With the Epytec flywheel item 639, you upgrade your BMW E46 330i Touring with M52/M54 engine from the factory dual-mass flywheel (DMF) to a precisely manufactured single-mass flywheel (SMF). The aim of the conversion is noticeably more direct response and a significantly more agile engine rev-up.

Thanks to the reduced rotating mass, the drivetrain reacts more spontaneously, which is especially noticeable during load changes and in sporty driving. At the same time, the system remains suitable for everyday use if the conversion is carried out cleanly according to specifications.

An additional advantage: Depending on the vehicle/transmission configuration, the conversion can be implemented using common clutch components. In addition, converting back to a DMF is generally possible if you later want to return to the factory characteristics.

Compatibility, variants & important preliminary check

Before installation, you must correctly identify the right clutch/transmission variant:

-

228 mm clutch: typically in combination with Getrag transmissions

-

240 mm clutch: typically in combination with ZF transmissions

Especially with older or already converted vehicles, the rule is: always check the transmission type and spline beforehand, and don’t order based on model year alone.

Check before you start:

-

Transmission type (5-speed/6-speed, Getrag/ZF)

-

Clutch diameter (228/240 mm)

-

Spline of the transmission input shaft (e.g. 10 or 22 teeth – depending on transmission version)

-

Condition of pilot bearing, release bearing, guide sleeve, crankshaft oil seal

2. Tools & Materials

For the conversion, you will need standard tools and a few specific aids. The following has proven itself in practice:

-

19 mm socket for the driveshaft and transmission mount

-

12 mm triple-square or hex socket for the pressure plate (depending on the clutch kit)

-

Torque wrench with adjustment to at least 110 Nm

-

Medium-strength threadlocker

-

Transmission jack or alternatively a sturdy trolley jack with a wooden support

-

Engine support bar or crane (recommended for longer transmission separation)

-

Clutch alignment tool for correct seating of the friction disc

-

Brake cleaner & rags

-

Wear safety glasses during removal and when handling brake cleaner!

Safety:

Raise the vehicle securely, disconnect the battery, secure the drivetrain against unintentional rotation.

3. Step-by-step guide

Start by removing the exhaust system, including the pre-cat flange, to gain access to the driveshaft. Then disconnect the driveshaft at the transmission output flange – carefully loosen it with light taps and an even twisting motion. After that, the transmission can be lowered in a controlled manner with a transmission jack and removed. Disconnect all electrical connections such as the reverse light switch and clutch master cylinder sensor beforehand!

Fit the clutch kit (e.g. Sachs XTend or LuK SAC), center the friction disc correctly, and bolt the pressure plate on in a criss-cross pattern using the supplied bolt set. Make sure the diaphragm spring engages cleanly and nothing is misaligned.

When reassembling the transmission, be sure that the release bearing runs correctly on the guide sleeve. Operate the clutch and check gear selection – the clutch pedal feel remains true to the original!

Experience shows: Even with sporty driving, the function of the original clutch is fully retained, including a clean engagement point.

Fit the clutch kit (e.g. Sachs XTend or LuK SAC), center the friction disc correctly, and bolt the pressure plate on in a criss-cross pattern using the supplied bolt set. Make sure the diaphragm spring engages cleanly and nothing is misaligned.

When reassembling the transmission, be sure that the release bearing runs correctly on the guide sleeve. Operate the clutch and check gear selection – the clutch pedal feel remains true to the original!

Experience shows: Even with sporty driving, the function of the original clutch is fully retained, including a clean engagement point.

Note on the clutch:

In principle, both Sachs and LuK systems can be used, provided they match the transmission splines and the diameter. Both systems work with a self-adjusting function (SAC/XTend) for constant pedal force over their service life.

When selecting, it’s not only “M52/M54” that matters, but above all:

-

Transmission version (5-/6-speed)

-

Input shaft splines

-

Clutch diameter

-

actual vehicle configuration (don’t go by first registration blindly)

For sportier driving, the 240 mm variant is often preferred, as it offers more thermal and torque reserve than smaller versions.

Additional notes on clutch selection:

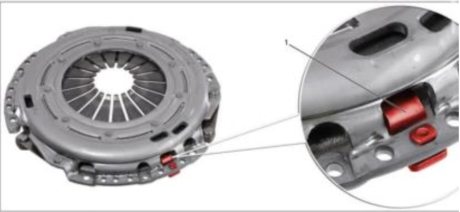

Both systems pursue the same idea: the clutch is intended to become more durable through automatic self-adjustment. I personally prefer the Sachs system (XTend Type I), however there is a small peculiarity when fitting it to the SMF. The installation specifications with regard to the housing stop are violated. The reason: the housing stop (marked in red in the image above) can no longer seat cleanly if the SMF support ring is no longer perfectly flat. This means that correctly resetting the adjustment mechanism can no longer be guaranteed. In such cases, the LuK clutch kits with SAC system are better suited.

Important to know: According to LuK and Sachs, clutch kits approved for models “up to 02/2003” (regardless of whether 228 mm or 240 mm) include a 10-tooth friction disc. This fits only the 5-speed transmissions S5D-250G and S5D-320Z. If, however, you have an E46 325i or 330i (M54) with 6-speed manual transmission or SMG, you need the clutch kit “from 03/2003”. This has 22 teeth and fits the main shaft of the GS6-37BZ (6-speed transmission 330i/325i). On the E36 models with M52 engines, the S5D-250G is usually installed again – so the 10-tooth disc is also mandatory here.

For sporty driving, I clearly recommend the 240 mm clutch kits from the E36 328i, E46 328i and 330i models. This allows better power transfer even at higher torque. The 228 mm clutches (sometimes also called 230 mm) from the smaller 6-cylinders (320i–325i), on the other hand, tend to slip fairly quickly with aggressive driving or on engines with more power.

-

5-speed (240 mm):

Sachs: part no. 3000 970 095

LuK: part no. 624 2333 00 -

6-speed (240 mm):

Sachs: part no. 3000 970 139

LuK: part no. 624 3158 00

Conclusion:

The quality is top-notch, the workmanship very commendable and the fit leaves nothing to be desired – this also applies to the original M52/M54 clutch kits. Add to that a pleasantly light weight and a fair price. Nevertheless, two small points of criticism remain: for one, due to the weight saving, the necessary support for the housing stop is missing with the Sachs kit. Secondly, there is no hole for locking the flywheel. This means that for work on the valve timing (timing chain, VANOS) in the future, you will be dependent on a dial gauge in the first cylinder.

I hope I was able to help you with this information and perhaps motivate one or two people to consider an SMF.

Additional notes on clutch selection:

Both systems pursue the same idea: the clutch is intended to become more durable through automatic self-adjustment. I personally prefer the Sachs system (XTend Type I), however there is a small peculiarity when fitting it to the SMF. The installation specifications with regard to the housing stop are violated. The reason: the housing stop (marked in red in the image above) can no longer seat cleanly if the SMF support ring is no longer perfectly flat. This means that correctly resetting the adjustment mechanism can no longer be guaranteed. In such cases, the LuK clutch kits with SAC system are better suited.

Important to know: According to LuK and Sachs, clutch kits approved for models “up to 02/2003” (regardless of whether 228 mm or 240 mm) include a 10-tooth friction disc. This fits only the 5-speed transmissions S5D-250G and S5D-320Z. If, however, you have an E46 325i or 330i (M54) with 6-speed manual transmission or SMG, you need the clutch kit “from 03/2003”. This has 22 teeth and fits the main shaft of the GS6-37BZ (6-speed transmission 330i/325i). On the E36 models with M52 engines, the S5D-250G is usually installed again – so the 10-tooth disc is also mandatory here.

For sporty driving, I clearly recommend the 240 mm clutch kits from the E36 328i, E46 328i and 330i models. This allows better power transfer even at higher torque. The 228 mm clutches (s

System-related noises with the SMF

After converting to a single-mass flywheel, additional transmission noises/vibrations may occur at idle or in the part-load range. This is inherent to SMF conversions by design and is not automatically a defect.

Depending on the vehicle, choosing a suitable transmission oil can improve the noise level.

4. Sources of error & troubleshooting

If unusual noises or grinding noises occur after the conversion, check:

-

Whether the SMF is correctly seated against the crankshaft

-

Whether the clutch cover was installed under tension

-

Whether the friction disc is correctly centered

-

Whether threadlocker was used (absolutely necessary!)

If shifting becomes difficult, there is usually an issue with the release travel or a poorly centered friction disc. In this case, it is recommended to dismantle everything again and rework it properly.

Click here for the matching product

- ✓ M52 & M54 engines

- ✓ 228 & 240 coupling

- ✓ lightens 5.8 kg

5. Safety & Liability

Safety has priority!

When working under the vehicle, always use axle stands or a lift. Never work using only a jack!

Wear safety glasses when cleaning with brake cleaner!

Disclaimer:

Carrying out the conversion is at your own responsibility. Epytec assumes no liability for consequential damage caused by improper installation. All work should only be carried out with full technical understanding or by a professional workshop.

6. FAQ for the installation guide

Question 1: Does the SMF also fit vehicles with the 6-speed transmission (GS6-37BZ)?

Answer: Yes, but be sure to note that clutch kits from 03/2003 with 22 teeth must be used. The earlier 10-tooth discs are not compatible.

Question 2: How does the driving behavior change with the SMF?

Answer: The engine revs up noticeably more freely, and throttle response improves significantly. Despite the 4 mm lower overall height, the pedal feel remains almost unchanged.

Question 3: Can I continue using my old clutch?

Answer: In most cases, yes! The Epytec flywheel is designed so that it is compatible with the original pressure plate and friction disc. Only if there is already heavy wear or the wrong clutch is installed should you choose a new kit.

Disclaimer

Please note that carrying out this installation is at your own risk. Epytec assumes no liability for damage or injury resulting from following these instructions. Make sure you understand all steps and take the necessary safety precautions.

And that's it! That's it!

We hope you have now installed everything successfully. If you still have questions or anything is unclear, don’t hesitate to contact us.

➡ Go directly to the contact form here (click here)