Brake caliper adapter custom configurator

- ✓ brake caliper adapter custom-made manufacturing

- ✓ for front und rear axle

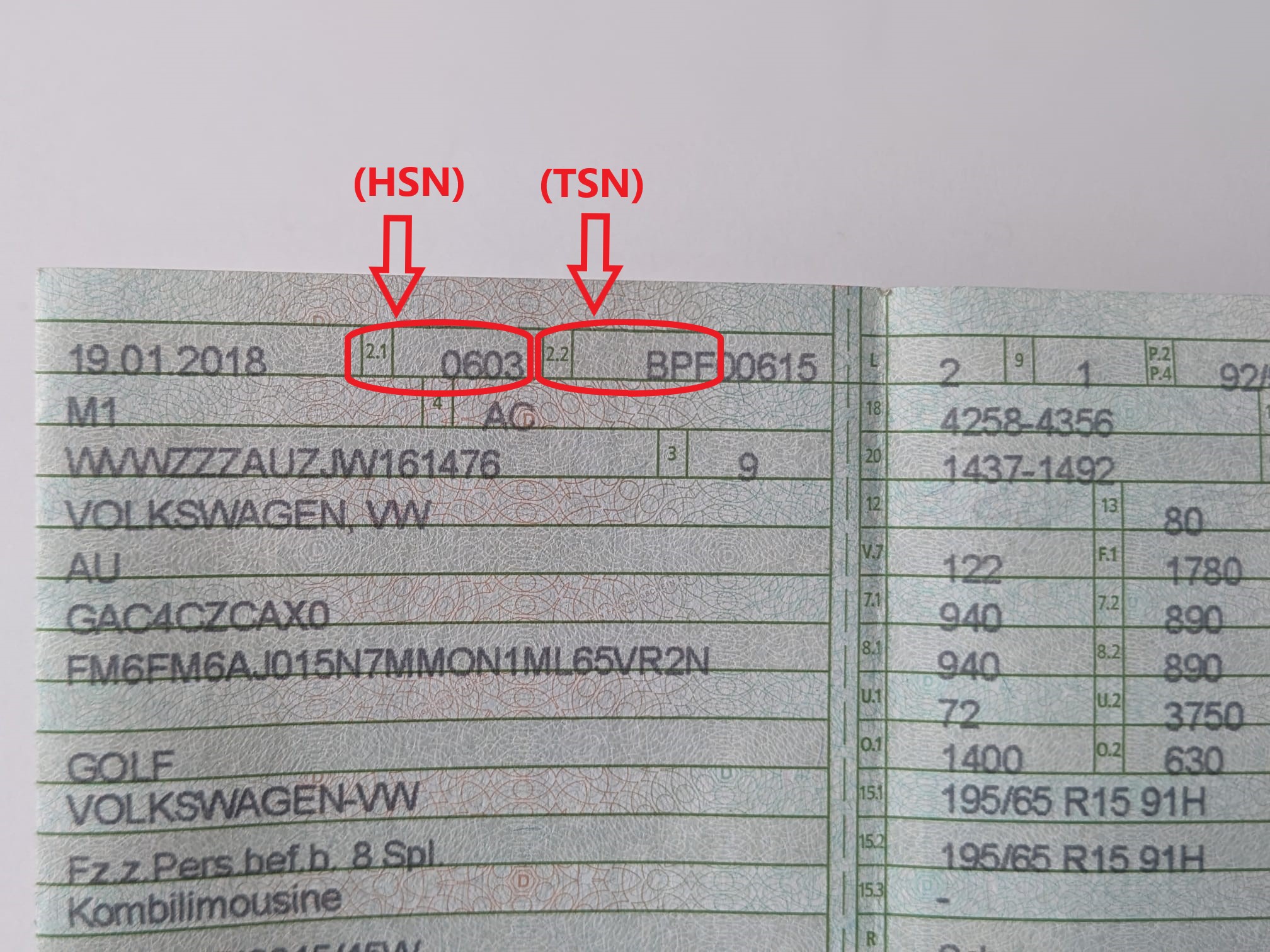

- ✓ information about the vehicle

€111.00*

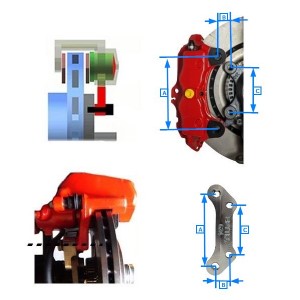

I-holder

I-holder

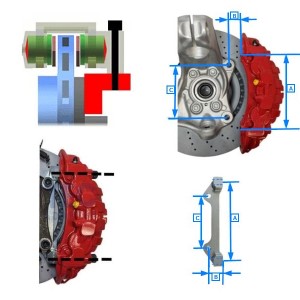

L-holder

L-holder

I do not want any screws

I do not want any screws

I would like suitable screws

I would like suitable screws

| Name | Title | Surcharge | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Simply create your desired adapter : | |||||||||||

|

|||||||||||

| Hole spacing brake caliper dimension A: | |||||||||||

| Distance axle mounting brake caliper dimension B: | |||||||||||

| Hole spacing wheel bearing housing dimension C: | |||||||||||

| Distance from axle mounting to brake caliper mounting Dimension D: | |||||||||||

| Hole spacing brake caliper dimension A: | |||||||||||

| Distance between axle mount and brake caliper Dimension B: | |||||||||||

| Hole spacing wheel bearing housing dimension C: | |||||||||||

| Distance from axle mounting to brake caliper mounting Dimension D: | |||||||||||

| Thread/diameter on the axle G1: | |||||||||||

| Thread/diameter on the brake caliper G2: | |||||||||||

| Accessories: | |||||||||||

|

|||||||||||

| Thickness steering knuckle screw holder dimension G1: | |||||||||||

| Thick brake caliper on screw holder dimension G2: | |||||||||||

Exclusive and individual: Brake caliper adapter according to your choice

We manufacture your brake caliper adapters for your desired components and for your vehicle.

Here is a selection for you, how customers have managed to mount their desired combination on their vehicle with the configurator.

Audi RS 4 Avant B7 brake upgrade to Mercedes AMG C63 brake system, click here.

Audi 80 Avant brake upgrade to RS2 calipers, click here.

To enable us to make the required brake caliper adapters for your project, we need a few data from you.

You can find out exactly what this data is by clicking through the individual steps of the configurator below.

In advance you will find the templates here to take your measurements on the vehicle.

>>print the PDF-template I-adapter, click here<<

>>print the PDF-template L-adapter, click here<<

Tips, information and hints:

- For a better ventilation of the brake system, we recommend removing the dust cover plates and brake anchor plates.

- We can generally not answer, which rim size you can mount after your brake conversion. There are simply too many different rims.

- In rare cases it is possible that the rims touch minimal the brake caliper, then you can simply use spacers.

>> Now directly to spacers << - Install the adapter with the necessary components and then check if new brake lines are required. Because, depending on the vehicle, the lines may be too short or the line tips may not suitable. We advise you to change to steel braided brake line because of the quality and technical advantage. Specifically for this, we have developed an online brake line configurator, where you can assemble the type of steel braided brake lines you want. Click here to go to the configurator

>> Configure steel braided brake lines <<

Please note that our articles have been designed for racing and motorsport. Use in public road traffic usually requires an individual approval in accordance with § 21 StVZO by an officially recognised expert. Further information can be found under TÜV Süd. For the individual approval, we will provide you with an expert opinion or material certificate, if available.

Login

9 May 2025 22:11

Christian K

Eine super Möglichkeit individuelle Projekte umzusetzen. Super Unterstützung bei der Anpassung und Klasse Support. Kann echt nicht meckern.

21 August 2025 08:53

Alexandre N

Très bonne communication et à l'écoute de vos attentes 👍🏽👍🏽👍🏽👍🏽👍🏽👍🏽👍🏽

5 July 2024 10:06

Matthias B

Support könnte besser sein!!!

- What material is used for the adapter?

A high-strength steel alloy is always used, made of special ST52 steel. This material is the most suitable for braking systems, and the TÜV (German Technical Inspection) usually registers this without any problems. Further information on the material certificate and corresponding information on TÜV registration is available under the following link

- How do I get a 50% discount chance?

If you provide us with your components and the part number, our team can check if this conversion may also be of interest to future customers. If this is the case, you will be informed by email. The total amount of the order is due in advance. As soon as you have installed and registered the brake caliper adapter, all you have to do is take nice pictures of the installed brake caliper adapter and the brake system and provide us with a copy of the vehicle registration document with the registration and you will receive 50% of the purchase price back from us.

- What do I have to pay attention to when selecting the components?

If you already know which brake calipers you want to install, all you have to do is get the right brake discs. It is worth investing a little time in this. With the right choice of the brake disc, you can save money in the future. You can also use brake discs from other manufacturers. Please note the following: The bolt circle (Pitch Circle Diameter) on the brake disc should match the original bolt circle on the vehicle. If this is not the case, we would be happy to re-drill your brake disc. The centering should match the original. It is very important that the brake disc has the right thickness for the brake caliper. It is up to you where you get the brake discs. In any case, we also have some on offer, from EBC or Zimmermann. Click here for a detailed application example.

- How do I best determine the dimensions and what do I have to pay attention to?

The first step is just to test if the components fit your vehicle. You don't need to hang out the brake line, but you can hang the original caliper on its side, e.g. with cable ties. It is important that the brake line is not kinked or subjected to excessive loads. Then you take the brake caliper and the brake disc and assemble them as a test. It is important that the brake caliper can be pushed fully onto the disc without hitting the steering knuckle. If that is the case, you can now take the dimensions. You can find out what measurements we need in our configurator. When taking measurements, you should make sure that the brake caliper sits straight on the disc and that the brake pad passes approximately 1mm under the disc. You can find out which dimensions we need in our configurator. You don't have to worry about taking absolutely 100% correct measurements, as you will get a free plastic model to test in advance. This allows you to make changes again if necessary. After you have received the 3-D model, you should assemble it once for a test. It is advisable to measure the brake line directly. If everything fits, you let us know and we will manufacture the adapters and deliver them to you.

- Do you need a different adapter shape than listed here?

If your adapter shape is not listed, we can of course also carry out the conversion, but not via the configurator, as these adapters are a little more special. More information here (click here)

- Print template for download

- What happens if I made a mistake while taking the measurements?

If you make a mistake while taking the measurements, this is not a problem, because in the first step you get the adapter with your specified dimensions made of plastic. Thus, in the worst case, the plastic model is wrong and you have the opportunity to correct the dimensions again without incurring additional costs.

- I would like that Epytec determine the dimensions. How to proceed ?

For this, we need the following components from you: steering knuckle, brake caliper, brake pads, brake disc. Then fill out the following form, attach it to the package and send it to the following address: Epytec GmbH / Neuhäuser 10/79244 Münstertal

- Material certificate

Material certificate for the technical control inspection

Here you can print an example of a material certificate in order clarify the situation with your inspector in advance. All our products (unless otherwise indicated) are subject to registration! Approval can be carried out by an expert in accordance with the law. For better classification and easier work to achieve the registration, we provide a material certificate, which has an EPYTEC logo. We recommend the expert that he includes the name of the manufacturer in the vehicle documents.

Here to an example of a material certificate

Tension /resistance analysis

In rare cases, a material certificate may not be sufficient for the expert. In this case, talk to the inspector to see if he can register the adapter with a resistance analysis. To do this, the link to the model can be simply sent to the controller. If he agrees, we can provide you with this summary form for a price of only ?50, while in the detailed form it costs more than ?500 (a detailed document that we cannot do internally) -> but this only applies to series adapters, not to custom-made products.

Here for the tension/resistance analysis example

- I / L mounting bracket dimension B

Distance from the center of the hole in the axle support to the brake caliper mounting bracket. When the caliper is fully seated on the brake disc, add approximately 1.5mm so that the brake caliper has enough space for the brake disc.

- I / L bracket dimension C

Hole spacing from the steering knuckle from the center of the hole to the center of the hole.

- I / L bracket dimension D

Distance between axle support and brake caliper mounting bracket. Place the caliper in the middle of the disc then measure the distance.

- 3D model

Prototype construction: 3D samples of production

Step by step towards the prototype

We have purchased a 3D printer and therefore can offer the construction of prototypes for every private and professional customer at affordable prices. If you order a custom-made product from us, you will even receive the samples for free.

This type of procedure is perfect for checking the correctness of the fit and, if necessary, recognizing changes before production. In addition, it significantly speeds up the process, as such a sample is created and can be sent in the same day.

What is necessary?

All we need is an STL file, sketch, draft or sample to include in the CAD and create an STL file from it.

If you ordered through the configurator, we have all the data and you will receive the plastic sample to test in the next few days.

Price

If an STL file is delivered, we can print the parts from 19.95 ?

If a sketch with dimensions is provided and we create an STL file using our CAD software, it is from 59.95 ?

Functional description of the 3D printer

Using a heated nozzle, the PLA plastic is melted and applied in layers until a finished model is created. We then provide this with a thread (if necessary). This means that even heavy components can be adapted on a test basis. We are always fascinated by the stability of the 3D patterns and the tightness of the screws.

Technical specifications

Maximum component size: 230 x 225 x 205 mm. Printing precision: up to 20 microns = 0.1 mm. Printing time: Example of brake caliper adapter as shown on the right works at an average resolution of approximately 11.30 hours \ "Funktionbeispiele-prototypenbau-epyteckIIyafLnoETLp \"

- Can I also use other brake discs as specified in the required components?

No, unfortunately that is not possible. The reason is simply: all brake calipers have different heights and depths. If another brake disc is installed, the brake caliper would either not fit on the adapter or not run in the middle of the brake disc. But if you want to install a different brake caliper, we also have an option for you. You can have a custom-made product made for you, take a look at the following link for more information: https://epytec.de/uk/custom-made-products/brake-technology/adapters-for-brake-systems

- Can I also use other brake calipers as specified in the required components?

No, unfortunately that is not possible. The reason is simply: all brake calipers have different heights and depths. If another brake disc is installed, the brake caliper would either not fit on the adapter or not run in the middle of the brake disc. But if you want to install a different brake caliper, we also have an option for you. You can have a custom-made product made for you, take a look at the following link for more information: