Custom-made engine mount for Mercedes W124 – 722.6 gearbox upgrade

Introduction & aim of the conversion

The conversion to the modern Mercedes Benz 722.6 automatic transmission (NAG1) is becoming increasingly popular, especially in the W124 community. This 5-speed automatic transmission offers noticeable advantages in terms of shifting comfort, efficiency and durability. To ensure smooth installation, a precisely fitting engine mount (transmission mount) is required.

This project involved the custom manufacture of a rear engine mount for the Mercedes Benz W124, suitable for all body variants (saloon, coupé, estate) with the exception of the V8 models. The aim was to find a universal solution for installing the 722.6 transmission in place of the older 722.3, 722.4 or 722.5 automatic transmissions – without any body modifications.

Technical details of the upgrade

The custom-made engine mount is based on the mounting points of the original Mercedes Benz gearbox mounts and uses factory bearing points.

Compatible engines

-

petrol engine: M102, M103, M104, M111

-

Diesel fuel: OM601, OM602, OM603, OM604, OM605, OM606

Original parts used

gearbox bearing: Mercedes Benz A2122400318, A2122400418, A2122400618 or A2122400818

-

Fastening screws (engine mount to gearbox bearing): 2x Mercedes Benz N000000008671 (M8x25x1, grade 8.8)

-

Fastening screws (motor mount to floor): 4x Mercedes Benz N000000008498

-

Washers (engine mount to floor): 4x Mercedes Benz N007349010007 (M10x25x1, grade 10.9)

These OE part numbers ensure that original fasteners and bearings can be used – plug and play without additional machining or special parts.

Implementation: Sketch from the customer

For this project, the customer provided their own technical drawing with dimensions. Based on this sketch, Epytec created a CAD drawing that served as the basis for the CNC production of the motor mount.

procedure

-

Checking the delivered drawing for technical feasibility

-

Creation of a standard-compliant production drawing in SolidWorks

-

CNC machining of the holder from high-strength steel

-

Delivery includes material certificate and documentation

This option is ideal for technically savvy customers who already have precise ideas or measurements.

Installation & assembly procedure

Installation is carried out using the original mounting points on the vehicle floor and the standard gearbox mount. Important:

The use of the OE screws and washers listed above is essential in order to correctly absorb the mechanical load.

FAQ

Question 1: How durable is the engine mount under load?

Our brackets are made of high-strength steel and are designed for standard and performance-enhanced engines. The material certificate proves their load-bearing capacity – even at high torques, for example in the OM606 biturbo conversion.

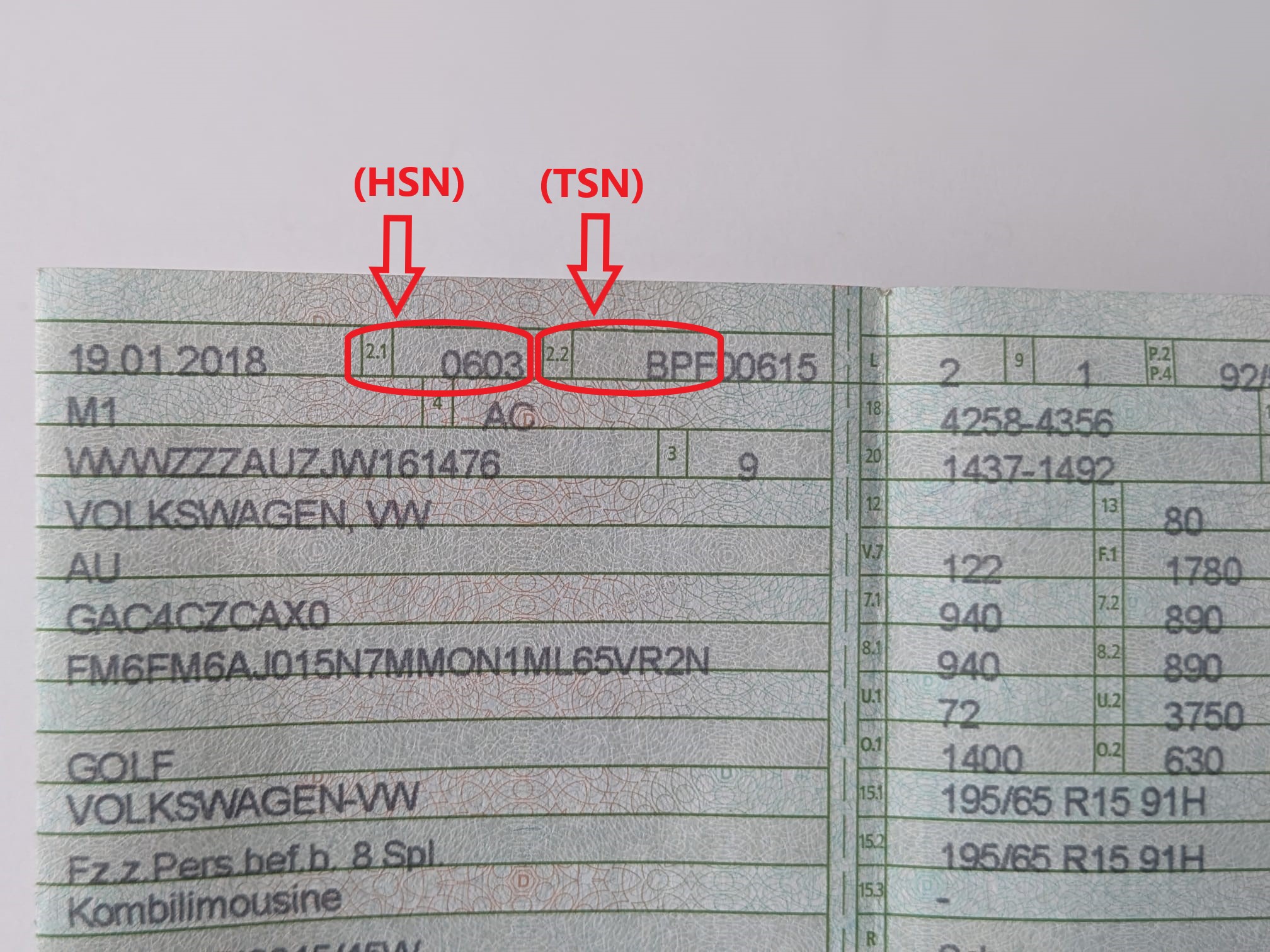

Question 2: Is it possible to register with the TÜV?

Yes, registration is possible without any problems via individual approval. We will provide you with a material certificate to submit to the TÜV – ideally in combination with a test report or proof of conversion.

Question 3: Can I reverse the conversion?

Yes, as the engine mount is designed to fit the original mounting points, it can be removed and replaced with a standard gearbox without any permanent modifications.

Question 4: What tools are required for assembly?

Standard tools are sufficient. An external hexagon bit (e.g. E10 or E12) is important, as Mercedes uses this design for its OE screws. A gearbox jack makes installation much easier.

TÜV & Approval

Registration via individual approval is possible. The material certificate for the manufactured bracket is supplied as standard. Approval should be carried out in consultation with a TÜV inspector (e.g. TÜV SÜD), ideally with documentation of the conversion and OE components used.

Here you will find a sample material certificate that you can provide to your examiner in advance (click here).

Conclusion & customer value

This custom-made product offers a durable, workshop-ready solution for converting the transmission to the 722.6 automatic transmission in the W124 – without welding or complex DIY modifications. Thanks to the use of original mounting points and OE components, the solution is not only robust but also TÜV-approved.

We can also help you find your individual solution.

Would you like a tuning conversion tailored to your requirements, just like this customer? Simply get in touch using our contact form. With over 15 years of experience, we can carry out your conversion quickly and cost-effectively.

Would you like the same gearbox combination for your vehicle (170526)? Then send us a message using the contact form, referring to the drawing or conversion. We will prepare a quote for you.

About Epytec

Epytec is a specialist in the manufacture of tuning adapters with over 18 years of experience. Our products, manufactured in Germany, stand for quality and innovation.

Tuning adapters connect components from different vehicles. For example, Porsche brakes can be adapted to a Golf GTI or Audi engines to VW transporters. This flexibility enables customised solutions.

Our commitment to the highest quality and customer satisfaction guarantees hassle-free TÜV registration. This makes Epytec the market leader for hobby tuners and professionals alike. With Epytec, you are choosing technology that is "Made in Germany".