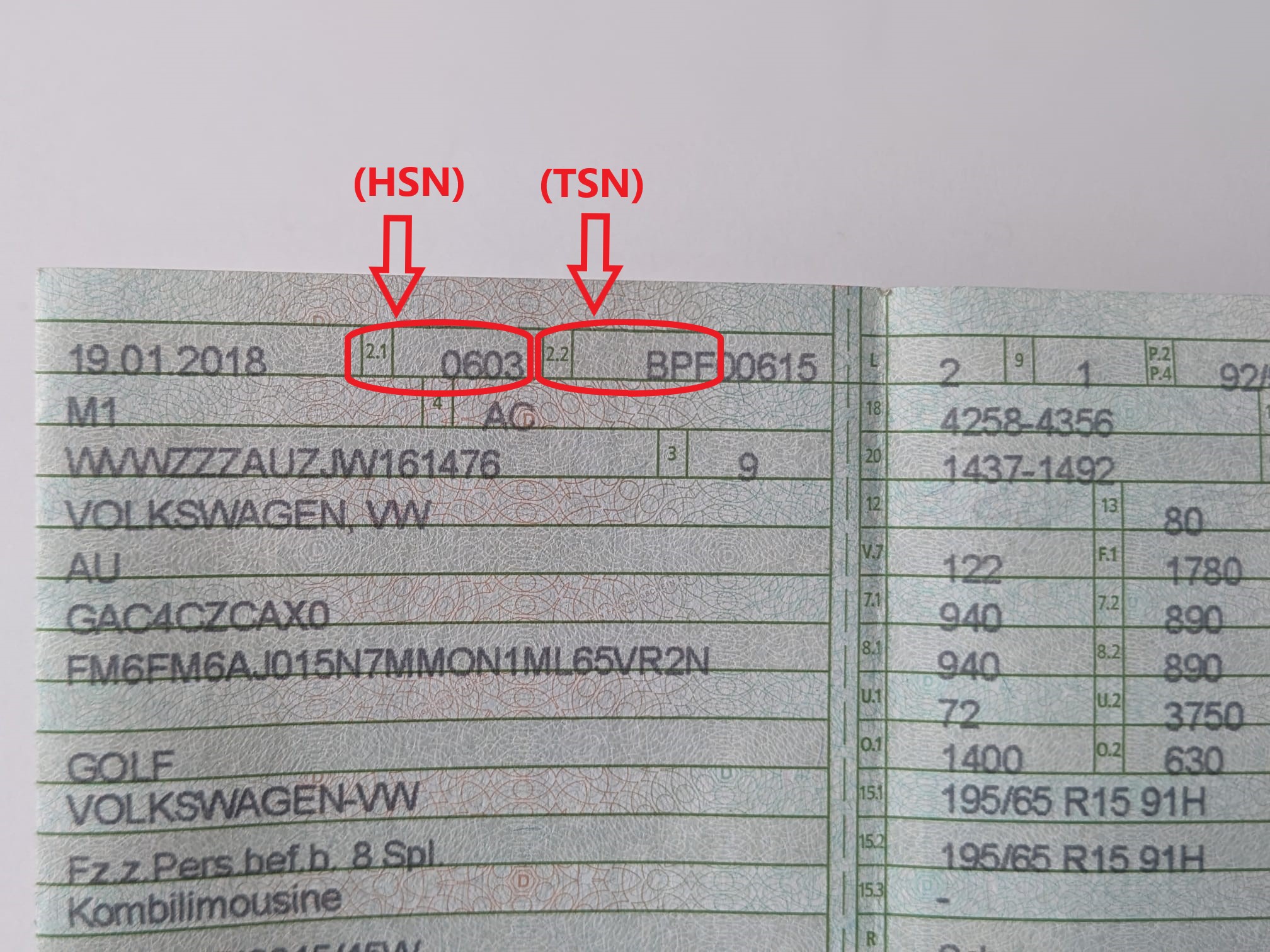

Installation instructions for the brake caliper adapter 1201 Mercedes Benz SLS on the rear axle of the W447

Here you will find step-by-step instructions on how to install the handbrake from the Mercedes-Benz E-Class W211 (2304200312) on the W447 / W639. This is absolutely necessary to ensure that the handbrake function is still available when converting to a larger brake disc and a larger brake system on the rear axle.

Please note

Please read these instructions carefully before starting work. If the conversion is too difficult for you, please commission a specialist company to carry out the installation. We cannot accept any liability for consequential damage caused by incorrect installation. Correct installation and adjustment will save you time, money and trouble.

What do you need for this?

- Depending on your technical knowledge, approx. 2-3 hours

- Torque spanner with suitable attachments

- Liquid threadlocker

Dismantling:

- Old brake system (brake disc, brake caliper and brake calliper carrier)

- Remove or machine the air baffle plate or brake backing plate or armature plate (we prefer to remove them, as the ventilation of the brake is better guaranteed).

- Remove the wheel hub, handbrake shoes and spreader plates from the wheel bearing housing

!!Important!!:

It is essential to check that there is no rust or paint residue on the screw-on points of the steering knuckle or wheel hub. If this is the case, please clean them. Then check the steering knuckle threads for damage.

- first the cast nipples must be ground flat

Furthermore, everything on the contact surface must be ground slightly flat (see picture).

This must be done so that the new 360x28mm brake disc from the Mercedes Benz GL (09.A907.11), which is slightly smaller in internal diameter than the original brake disc, can be fitted cleanly and does not protrude or grind anywhere.

After sliding the cut anchor plate over the already mounted wheel hub, it became clear that it was not lying flat on the wheel bearing housing in several places. The reason for this are factory-pressed beads and raised areas in the armature plate, which are necessary for the original series design, but interfere with the conversion.

In order to ensure a flat and tension-free installation, these areas - circled in blue in the picture - must be professionally tapped flat with a soft-face hammer. It is advisable to first place the anchor plate on a trial basis and mark the contact surfaces with a felt-tip pen. The moulding can then be carefully carried out on a vice or a flat metal plate. Caution: Only work with a controlled hammer blow so as not to deform or break the sheet too much.

This measure shifts the position of the handbrake shoes slightly further towards the centre of the vehicle, which leads to a deviation from the target position on models with an electronic parking brake. For this reason, it was then necessary to recalibrate the electric handbrake via the Mercedes diagnostic system to ensure correct function and even brake force distribution.

💡 Experience: The repositioning of the jaws had no influence on the mechanical actuation itself - the only decisive factor was the control logic, which had to be relearned after the conversion using the original Mercedes workshop software. Be sure to include this in your plans if you carry out a similar conversion!

When the handbrake shoes were first fitted, it became apparent that they could not be closed far enough for the parking brake to be actuated properly. The reason for this was that the closing distance was shortened by moving the shoe position towards the centre of the vehicle as described above, while the material thickness on the inside of the pads remained unchanged.

The solution was to carefully grind down the centre of the handbrake shoes on the inside (marked in red) using an angle grinder and a fine flap disc. Make absolutely sure that only the protruding contact edges are reduced without damaging the friction linings. It is usually sufficient to remove approx. 1-1.5 mm of material on each side so that the jaws are free of play and the mechanism can grip correctly again.

Practical tip: When grinding, it is advisable to remove the entire friction lining beforehand or to cover it carefully to avoid contamination from grinding dust. Then clean all machined areas with brake cleaner.

In addition, it was found that the original tensioning travel of the standard handbrake cable tensioner was no longer sufficient to establish the mechanical pre-tension of the brake. A longer Allen screw was therefore inserted into the tensioner, which was also provided with a slot in the screw head. This means that it is still possible to adjust the handbrake even when it is installed - either with an Allen key or a slotted screwdriver. This solution is easy to implement, fully retrofittable and enables precise fine adjustment of the handbrake with increased leverage.

🔧 Important: When inserting the longer screw, make sure that the threads in the tensioner are fully engaged and that the screw does not protrude beyond the end to prevent the mechanism from jamming or blocking.

The handbrake can now be reinstalled on the wheel bearing housing.

All you need to do is fit the brake shoes for the Mercedes-Benz E-Class W211 (2304200312). You can find them here (click here)

The huge advantage here is that the spreader plates for the handbrake from the Mercedes Benz W447 / W639 can still be used and do not have to be converted to those from the Mercedes Benz E-Class.

If you want to continue using the anchor plate / heat protection plate, this must be slightly adapted.

The tuning Epytec adapter can now be fitted.

It is important to ensure that the adapter with the Epytec lettering and engraving is attached to the inside of the vehicle so that the TÜV inspector can easily read the engraving during approval.

!! Tipp !! Use threadlocker.

The Mercedes Benz SLS C197 AMG 4-piston brake caliper (part number: A1974232798 / A11974232898) can now be bolted on.

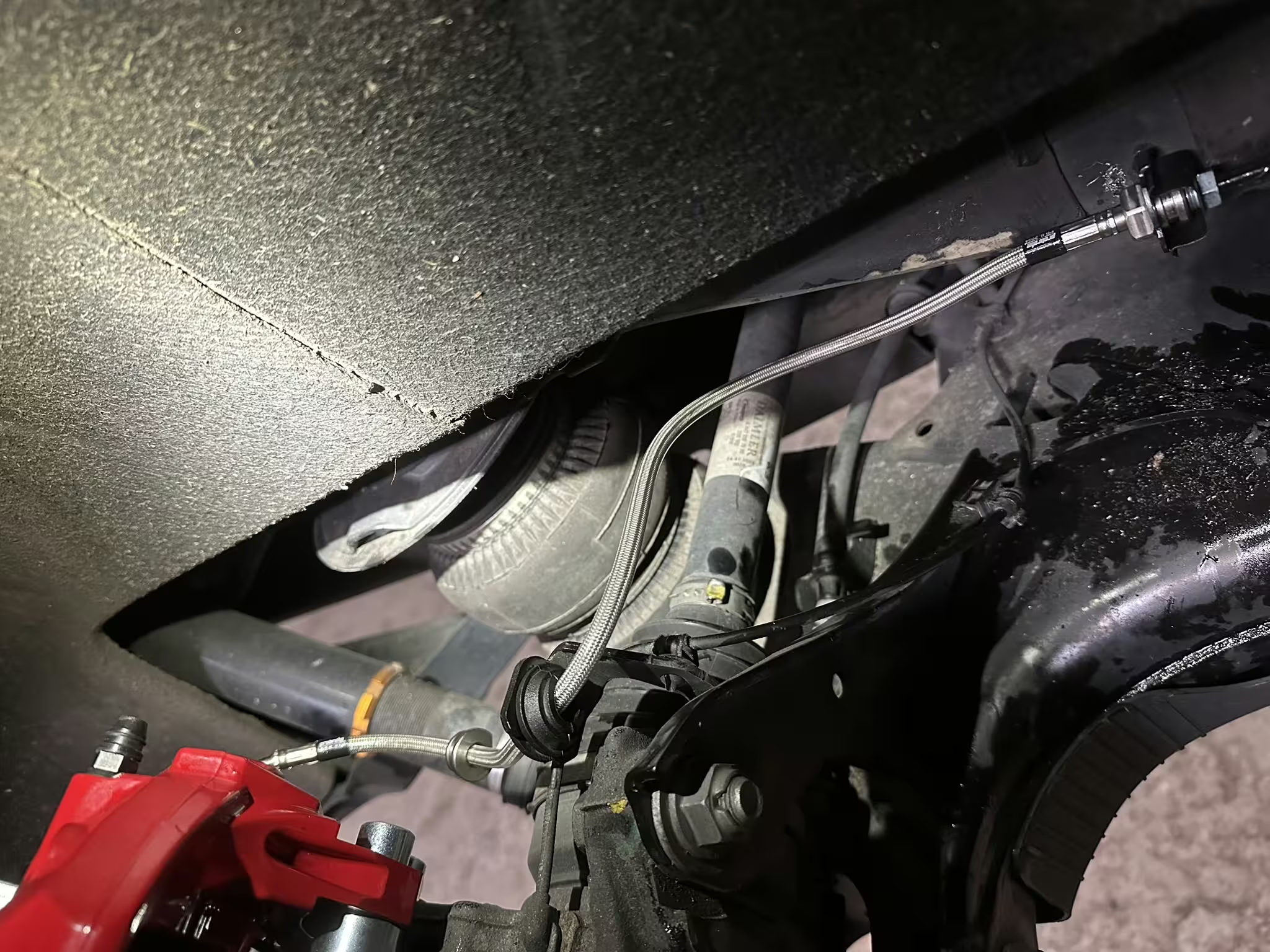

You can then reconnect the brake lines and bleed the brake completely. For this conversion, it is recommended to convert directly to steel flex brake lines.

Click here to go directly to the appropriate steel flex lines (click here )

- These have the following advantages:

- No pressure loss when the brakes are applied, noticeably more precise pressure point

- No swelling as with rubber lines

- Cost savings, as steel braided lines have an almost unlimited service life and do not have to be replaced every 3-5 years

- Shorter braking distance

- Marten protection

- Optics

The handbrake servomotor can now be relearned and everything works as it did before :)

Suitable steel flex lines were supplied for the conversion, the length of which fits perfectly between the brake calliper and the vehicle body - no pulling, no slippage, optimum installation even at full steering lock and in a sprung state. The lines were easy to fit to the connection threads and tighten with the required torque.

However, a small design deviation became apparent during installation on the bodywork: the original retaining plate, on which the cable and brake hose are screwed together with a union nut in the standard version, was not compatible with the outer diameter of the new steel flex connection. The stainless steel fitting of the steel flex line is slightly larger than the standard fitting and could not be fed through the original hole.

There are two tried and tested solutions for this case:

Unscrew the connection piece of the steel flex line: If you remove the connection piece of the line cleanly, you can thread the line through the original retaining plate and then screw it back on. When doing this, it is essential to ensure that the thread is clean and does not tilt.

Carefully widen the hole in the retaining plate: Alternatively, you can widen the hole in the original retaining plate to approx. 12-13 mm using a tapered drill or milling cutter - this will allow the union nut of the steel flex line to fit through without any problems. Work slowly and with little pressure to avoid tearing or distortion of the plate. Then deburr all sharp edges to prevent chafing on the brake hose.

💡 Experience: The second method is particularly suitable if you need to loosen or adjust the line frequently, as it is a clean, permanent solution. Both variants are technically equivalent, the only important thing is that the cable is mounted without tension and the fastening is free of play.

Safety note: After installation, always check the line connection for leaks under pressure - no brake fluid may leak out!

Once the complete brake system, including the brake disc, has been fitted, it must be checked that everything moves freely and that the brake system is not touching or rubbing anywhere.

Now you can refit the rim.

When fitting the rim, make sure that the brake caliper does not rub against the rim.

If this is the case, you can counteract this with track plates if necessary, so that the rim has enough distance to the brake caliper.

The TÜV generally requires a minimum distance of 3 mm.

Click here for our track plates (click here)

The conversion with the Mercedes Benz SLS C197 AMG 4-piston brake caliper (part number: A1974232798 / A11974232898) and the conversion to the handbrake shoes of the Mercedes-Benz E-Class W211 (2304200312) is now complete.

Here is the matching product for the installation instructions

- ✓ 360x26 A1974230112 / 1974230112 Mercedes GL brake disc

- ✓ 4-piston A1974232798 / A1974232898 Mercedes SLS C197 brake caliper

- ✓ rear axle

- ✓ 1994200020 / 2304200312

- ✓ OEM quality

- ✓ Mercedes E-Class. (W211 / S211 / VF211) and much more.