Pilot Bearing Ball Bearing SKF Flywheel

- ✓ pilot bearings

- ✓ ball bearings

- ✓ coupling

£12.79*

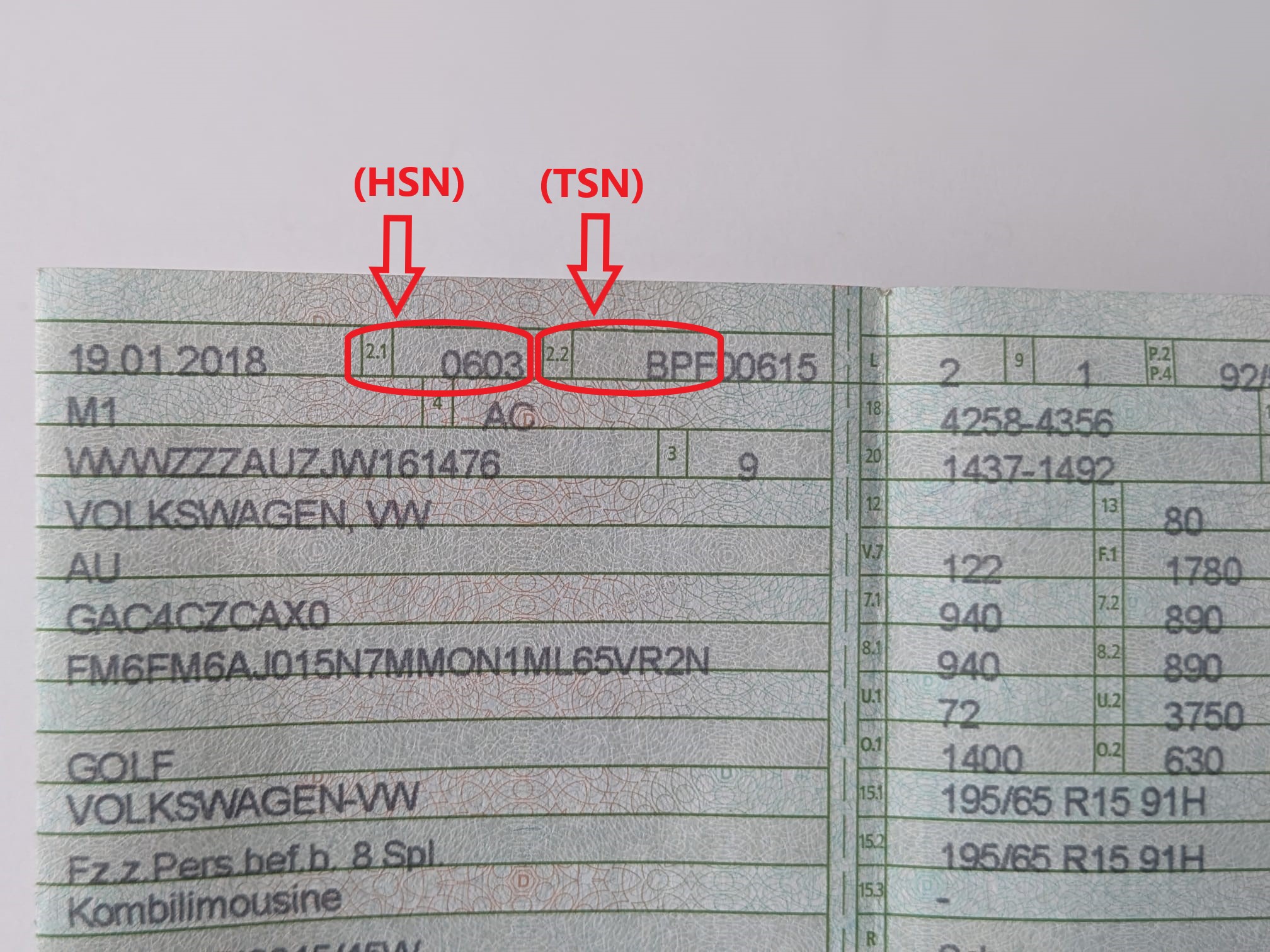

- Easy TÜV registration

- Quality Made in Germany

- Fair prices without middlemen you buy directly from the manufacturer and developer of the product

- Worldwide no. 1 in tuning adapters

- 15 years expert knowledge

- 10 years warranty

If the pilot bearing is too worn, the transmission shaft can no longer be led properly and it results to wear on the clutch parts and the transmission bearing.

Therefore, this ball bearing is ideal as a replacement part.

The pilot bearing is also suitable for some of our flywheels, see matching accessories.

technical data:

- outer diameter: 32mm

- inner diameter: 15mm

- height: 9mm

Delivery

- 1x SKF pilot bearing / ball bearing for flywheel

Login

- Which screws can be used?

The original bolts can be reinstalled.

- Which clutch can be used with the Epytec flywheels?

In general, the original clutch including the pressure plate can continue to be used with our Epytec flywheels. Alternatively, sport or performance clutches can also be used, provided they match the original clutch in design, diameter, and spline specification.

Before purchasing, please confirm with the respective clutch manufacturer that the clutch is identical in design to the OEM version. If this is the case, it will be 100% compatible with our flywheels.

In many cases, we can also supply the appropriate components directly. Depending on the application, this means we can recommend and deliver a suitable clutch disc as well as a matching pressure plate that are optimally matched to our flywheels. Simply contact us for advice ? we will be happy to help and put together a suitable solution.

Important note on the use of single-mass flywheels

Many vehicles are equipped as standard with a dual-mass flywheel, which actively dampens engine vibrations. If a single-mass flywheel is used instead in combination with a standard OEM clutch, unwanted side effects may occur, as the original clutch is not designed to compensate for the lack of damping.

This may lead to the following issues:

- Shuddering and vibrations, especially at idle or low engine speeds

- Uneven take-off behavior

- Increased load on the clutch and transmission

- Accelerated wear of the clutch disc

- Partial noise generation, e.g. gearbox rattle

For the use of a single-mass flywheel, we therefore generally recommend a clutch disc designed for this application with reinforced torsion springs, along with a matching pressure plate. Only in this way can the missing damping of the original dual-mass flywheel be effectively compensated, ensuring smooth and durable operation.

- What is the friction coefficient of the flywheel?

In principle, the friction coefficient can be assumed to be at least the same as that of the original cast disc. Due to the higher alloyed steel, our pulleys are slightly better than the original cast pulley. Of course, the material of the friction disk also has a major influence here; this must be checked with the manufacturer of the friction disk

- What material are the flywheels made of?

The flywheel is made of 16MnCr (chromium molybdenum) steel, which means it has a density of 7.76 kg/dm³

- Does the flywheel have a TDC marking and other markings for the ignition?

The flywheel has no TDC marking, only the pin on the back, just like the original flywheel. Tip: To adopt the TDC marking, the original flywheel must be turned to the TDC point before disassembly and the new flywheel must be marked in exactly this position.

- Does the flywheel have the default unbalance or is it balanced to zero?

The flywheel is supplied with the default unbalance. Unbalance can be created as follows! We first balance the pulley to 0, then apply a test mass at the specified point, which corresponds exactly to the unbalance. The pulley is then balanced to 0 again with the test mass. If you now remove the test mass, you have exactly the specified unbalance.

- Do we only sell the ring gear / gearwheel of the flywheels?

No, we can only sell the flywheels complete.

- Why do I have to run in my clutch?

The principle of a clutch is similar to that of a brake system. The different materials / surfaces must first adapt to each other. This happens through friction. With standard clutches or organic linings, this happens relatively quickly, as the lining material is "softer" than with sintered metal linings.

- Should the starter motor be replaced when converting to a single-mass flywheel?

Yes, we recommend replacing the starter motor at the same time as converting to a single-mass flywheel (SMF), if it hasn't already been done.

The conversion slightly alters the engine's vibration and starting characteristics, which puts the starter motor under greater mechanical stress. A new or rebuilt starter motor ensures reliable starting and significantly reduces the risk of wear or starting problems.

Since the starter motor is easily accessible when replacing the flywheel anyway, the additional work is minimal, while the reliability and longevity of the entire system are significantly improved.

In conclusion: If the starter motor hasn't already been replaced, it should be replaced as a precaution when converting to a single-mass flywheel.