Parts certificates for Epytec - The path to TÜV approval

In recent years, we have noticed that the 21 individual approvals for brake systems have become increasingly complicated, time-consuming and expensive.

For our customers, this often meant long waiting times and high additional costs in order to have their brake systems legally registered. We have therefore decided to offer our Big Brake Kits directly with a parts certificate - for quick, easy and cost-effective registration.

Maximum safety and TÜV-certified quality were our top priorities. To ensure that our braking solution meets the highest requirements, we tested one of our latest kits under extreme conditions - directly on our company car. The result: successfully passed!

The brake kits used were as follows:

🔹 Front axle: Epytec 6-piston-brake system with 375x36 mm brake discs

🔹 Rear axle: Epytec 4-piston-brake system with 356x22 mm brake discs

With this combination of powerful Porsche brake callipers and high-quality, perforated brake discs, we guarantee outstanding deceleration, optimum heat dissipation and consistent performance - even under extreme loads.

In the following report, we take you on the road to TÜV approval and show you how our Epytec Big Brake Kits were put through their paces

Trip to TÜV SÜD - The first step towards registration

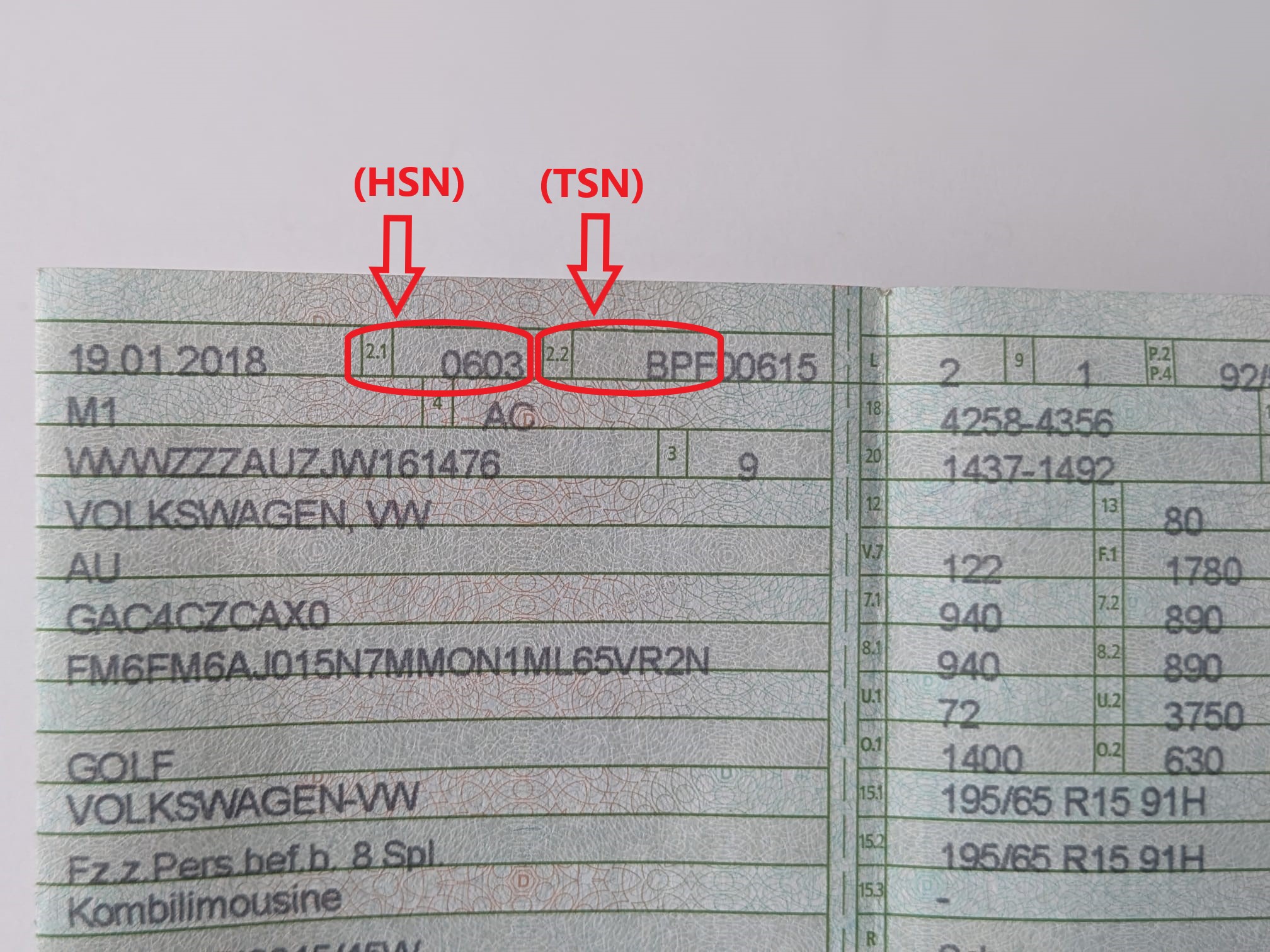

To obtain the parts certificate for our brake kits, we first travelled to TÜV SÜD in Munich, where the tests were carried out. Our test vehicle, a VW Touran with an MQB platform, was fitted with our Big Brake Kit and put to the test. The aim was not only to test pure braking performance, but also to demonstrate safety in extreme situations.

Test preparations

After the car had been driven into the test hall, we started with the preparations for the measurements and the successful parts certificate.

Our aim was to create a detailed analysis of braking performance in various situations. Several adjustments were made to carry out the tests under realistic conditions.

These included, among others:

- The installation of measuring sensors on the brake pads

- The installation of a pressure sensor on the accelerator pedal to ensure constant test conditions

- Routing all cables in the interior to record precise data while driving

What was done in detail? - Measurement of temperature and pressure

A key component of these tests was the integration of a temperature sensor into the brake pads. A system for continuous temperature monitoring was installed by drilling into the side of the brake pads. This provided the TÜV test centre with important information about the heat development of the brake discs under high loads.

In addition, a pressure sensor has been fitted to the accelerator pedal to ensure that the same pedal force is applied during each brake test. This is particularly important in order to obtain reproducible results and provide realistic values for the test protocols.

Routing the cables - monitor all data in real time

During the tests, all sensor data was recorded in real time inside the car. A specially set up measuring system with a laptop recorded all values, including:

- Brake pressure in the lines

- Temperature rise of the brake discs

- Deceleration values at different speeds

In addition, a GPS sensor was mounted on the roof of the car to enable precise recording of speeds and decelerations during the tests.

Extreme test - simulation of the maximum load

To test the behaviour of the brake system under maximum load, we overloaded the car with 300 kg of additional sandbags. This allowed us to simulate the extreme case of a fully loaded vehicle with several passengers and heavy luggage.

The challenge was to ensure optimum braking performance even under this increased load. Our aim was to validate the deceleration values not only on paper, but also in the real test environment under the toughest conditions.

Various tests and conversions on site

During the tests, the brake configuration was changed several times in order to compare different setups:

- Front original - rear 4-piston brake

- Rear original - front 6-piston brake

- 6-piston front, 4-piston rear

- Completely original brake system

- Completely converted Epytec Big Brake Kit

A final and extremely important test consisted of simulating a brake failure. For this purpose, a front brake calliper was opened in order to check how the vehicle would behave in an emergency situation.

The result was impressive: despite the failure, the vehicle pulled exactly straight ahead and remained fully controllable. This finding confirms that our brake system offers maximum safety and functions reliably even in exceptional situations.

The TÜV inspector is delighted

After numerous tests, the TÜV inspector's conclusion was clear: the braking system was convincing across the board.

Particularly emphasised were:

- Excellent braking performance at high speeds

- Optimum heat dissipation thanks to the perforated brake discs

- Constant deceleration during repeated emergency braking manoeuvres

The results of the tests showed that our brake kit not only fulfils the legal requirements, but even exceeds them.

Summary- maximum security and performance for our customers

After an extensive series of tests, numerous conversions and detailed measurements, we have now received official TÜV approval for our Epytec Big Brake Kit. We can now say with full conviction: This brake system offers maximum safety and performance for all MQB vehicles.

Our customers can rest assured that they are getting one of the best braking solutions available with our kit - tested under the toughest conditions and with official TÜV certification.

Here are the matching brake systems

- ✓ 375x36 1664210912 Mercedes ML / GL brake disc

- ✓ 6-piston 7PP615149J / 7PP615150J Porsche Cayenne 958 GTS brake caliper

- ✓ front axle

- ✓ 356x22 4H0615601F Audi A6 A7 brake disc

- ✓ 4-piston 996352421 / 996352422 Porsche Cayenne brake caliper

- ✓ rear axle

Summary: The first milestone - and the journey continues!

With this first successfully completed parts certificate, we have reached an important milestone. It has been a long journey - over a year of intensive work, countless tests and huge investments to get this project ready for series production. But the result speaks for itself: a TÜV-approved brake system that offers maximum safety and at the same time enables quick and uncomplicated registration.

But this is just the beginning! Our aim is to gradually create parts certificates for more and more of our products in order to be able to offer our customers an even wider selection of brake systems and adapters that can be registered immediately. We are aware that this process is not only extremely time-consuming, but also very expensive. Each expert opinion requires extensive testing procedures, several TÜV appointments and detailed documentation - an effort that we are happy to take on in order to guarantee you the best possible quality and safety.

We are already working flat out on the next parts certificates, but it will be some time before further kits are available. Until then, we look forward to setting a new standard with these two officially approved Epytec Big Brake Kits - for more safety, performance and easy registration without 21 mm approval.

Stay tuned, because we still have a lot planned!

About Epytec

Epytec is a leading specialist in the manufacture of tuning adapters, with more than 17 years of experience in the industry. Our products, which are manufactured entirely in Germany, stand for quality and innovation. Tuning adapters are essential connectors between car parts that make it possible to combine components from different vehicles. Our adapters make it possible, for example, to adapt a high-performance Porsche brake to a Golf GTI or to install a powerful Audi engine in a VW Transporter. This flexibility enables individual adaptations and optimisations that would otherwise not

Our commitment to the highest quality standards and the satisfaction of our customers is also reflected in our service. We guarantee trouble-free registration with the TÜV, which gives our customers security and confidence in the legality of their conversions. This combination of first-class products and excellent customer service has made Epytec a market leader that inspires hobby tuners as well as professional mechanics and vehicle builders. With Epytec, you are opting for proven technology "Made in Germany" that not only makes your vehicle more powerful, but also more